BLOG

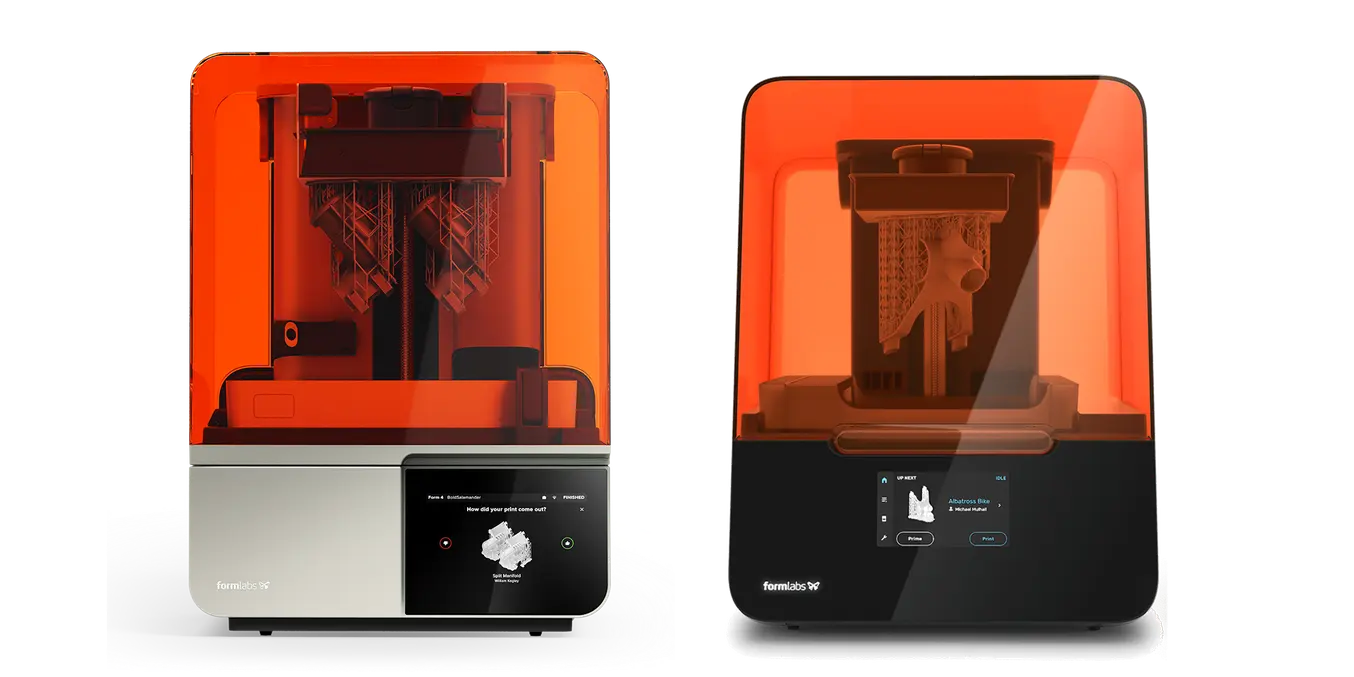

Formlabs Form 4 vs. Form 3 Comparison: Upgrades and Improvements

When it comes to high-quality resin printing, Formlabs is a name that stands out. Their latest release, the Formlabs Form 4, has sparked interest among 3D printing enthusiasts and professionals, prompting a comprehensive look at the Formlabs Form 4 vs. Form 3 comparison: upgrades and improvements. This article explores the distinct advancements in the Form 4, showcasing how these enhancements can significantly impact business operations, prototyping, and creative projects.

Introduction to the Formlabs Series

The Formlabs series of 3D printers has consistently led the way in innovation and quality in the additive manufacturing industry. Known for their precision and reliability, these printers serve a wide range of applications, from jewelry design to dental and engineering fields. Over the years, Formlabs has continuously refined their printers, addressing user feedback and technological advancements. The Form 3 made notable strides in accessibility and usability, but the introduction of the Form 4 heralds a new era of enhancements that promise to redefine industry standards.

Overview of Form 3

The Formlabs Form 3, launched in 2019, broke ground with its advanced Low Force Stereolithography (LFS) technology, making it easier to produce highly detailed parts with smoother finishes. The machine featured a 5.5-inch display, improved UV laser scanning system, and the capability to handle various materials, including standard resins, dental resins, and engineering materials. A standout feature included its cloud-connected ecosystem, streamlining design-to-print workflows and making it ideal for businesses scaling their 3D printing operations.

Despite its advantages, users identified areas for improvement. Issues like print speed and compatibility with new material types were frequently mentioned, leading to widespread anticipation for the subsequent model. The Form 3 was crucial in upping the ante in the resin printing game, providing a solid foundation for enhancements in the Form 4.

Introduction of Form 4

The Form 4 was unveiled with a promise of bridging the gap left by its predecessor. With a blend of user-driven upgrades and technological innovations, it aims to meet the demands of professionals needing not just high-quality prints but also efficiency and versatility. Speculative insights indicate that the Form 4 has been designed with both seasoned professionals and newcomers in mind, allowing various industries to reap the benefits of advanced 3D printing technologies. Features like expanded connectivity, advanced materials, and enhanced speed lead the charge in establishing the Form 4 as a formidable successor in the Formlabs lineup.

Key Upgrades in Form 4

As we delve into the key upgrades that differentiate the Formlabs Form 4 from the Form 3, it is essential to appreciate the impact of these improvements on workflow and results.

Enhanced Print Speed

One of the most significant upgrades in the Formlabs Form 4 is its print speed. Speed is a critical factor for users who frequently engage in high-volume production runs or require rapid prototyping for testing and validation. The Form 4 has introduced a more sophisticated laser system that accelerates the printing process without compromising quality. Formlabs claims that this model can complete prints up to 30% faster compared to the Form 3.

By implementing innovative techniques that enhance the curing process, the Form 4 minimizes layer bonding time, allowing for quicker build times across various materials. For instance, a complex model that could take 12 hours to print on the Form 3 now has the potential to be completed in approximately 8–9 hours using the Form 4. This improvement can be especially beneficial for industries that require tight deadlines, such as medical device prototyping or jewelry design.

Improved Resolution

Resolution is paramount in 3D printing, particularly for applications demanding intricate details. While the Form 3 already offered impressive print resolution, the Form 4 has substantially enhanced this feature by optimizing laser technology and the image processing algorithms. The Form 4 supports a resolution of up to 25 microns, which enhances the ability to reproduce fine details—such as text engravings and complex geometrical shapes—that may not have printed optimally on the previous model.

Furthermore, improved layer adhesion characteristics in Form 4 deliver not only better surface finishes but also reduce the chances of errors during the printing process. This shift allows creators in fields such as prototyping, education, and manufacturing to produce prototypes that are virtually indistinguishable from the final product. Whether creating dental aligners or bespoke jewelry pieces, the added resolution can elevate results, ensuring client satisfaction and trust in the job’s quality.

New Materials Compatibility

Another area where the Form 4 shines in the Formlabs Form 4 vs. Form 3 comparison is material compatibility. With advancements in technology, the Form 4 broadens the possibilities by supporting a wider range of materials, including new specialized resins tailored for specific applications. For example, the introduction of advanced engineering resins—combining strength, flexibility, and high-temperature resistance—enabled users to tackle more demanding projects.

As businesses increasingly adopt specialized materials for their workflows, this expanded compatibility enhances the printer’s appeal significantly. In industries like automotive and aerospace, where specific performance attributes are critical, the ability to print with high-strength composites can shorten development cycles and lower costs. Expert insights note that having access to a diverse material library also fosters innovation, leading to new product developments and designs that were previously infeasible with the Form 3.

Performance Analysis

In examining the overall performance between the Formlabs Form 4 and Form 3, it becomes evident that several factors contribute to their operation quality and usability.

Comparison of Print Quality

When comparing print quality, both the Formlabs Form 4 and Form 3 demonstrate remarkable capabilities in producing well-defined prints with high detail resolution. However, the Form 4’s advanced optical technologies have enhanced the clarity and smoothness of prints even further. The use of specialized optics and a more refined laser system contributes to minimizing light scatter, which can often lead to softer edges or imprecise features in the final product.

This difference can be critical for artists and manufacturers alike, particularly when the aim is to produce products that require not just functionality, but also visual appeal. For example, the precision required in jewelry design—where even the slightest imperfection can detract from value—highlights the importance of such enhancements.

Additionally, independent testing and reviews have reported that users of the Form 4 experience fewer layer misalignments and defects, showcasing reliability in high-volume printing requirements. Real-world application examples indicate that the improvements yield tangible benefits, with clients reporting increased satisfaction in the overall product quality.

In this extensive analysis of the Formlabs Form 4 vs. Form 3 comparison, it is clear that the Form 4 makes significant strides in areas that matter most to users, setting a new benchmark in the resin 3D printing landscape.

Speed and Efficiency

In the realm of 3D printing, speed and efficiency are crucial factors influencing productivity and turnaround time. The Form 4 boasts several advancements over its predecessor, the Form 3, particularly in printing speed and workflow efficiency. Formlabs has integrated a new optical architecture and refined the printing process. The Form 4 achieves a significant increase in throughput due to its enhanced laser system, which can manufacture parts at a faster rate and with greater precision.

For instance, while the Form 3 has a maximum build speed of approximately 40 mm/hour in certain materials, the Form 4 has shown capability to reach speeds of up to 50 mm/hour, translating to an almost 25% improvement in printing time in optimal conditions. This improved speed can accelerate the production process, which is especially advantageous for industries such as jewelry, dental, and prototyping, where time-to-market is critical.

Efficiency also extends to the post-processing phase. The Form 4 incorporates a more streamlined approach to support removal and wash times, allowing users to spend less time on cumbersome manual tasks and more on value-added activities. With the introduction of the new High-Temperature Resin, the Form 4 can process forms with intricate geometries and fine details while reducing the need for extensive support structures, thereby minimizing material waste and cleanup times.

Overall, these enhancements in speed and efficiency not only increase productivity but also enable users to take on more projects and respond swiftly to client demands.

User Experience

User experience plays a pivotal role in the overall satisfaction and efficacy of any 3D printing system. Formlabs has made notable strides in enhancing the user experience in the Form 4 when compared to the Form 3. The introduction of an intuitive touchscreen interface on the Form 4 simplifies the navigation between settings and operational functions. Users can easily adjust print parameters, monitor print status, and manage resin levels directly from the machine, offering a more fluid interaction than the Form 3’s controls.

Moreover, the Form 4 includes smarter connectivity options, such as enhanced Wi-Fi capabilities. This allows for seamless integration with cloud software and the ability to send print jobs remotely. In today’s fast-paced environments, the minimized downtime and improved accessibility offer considerable advantages. For example, users can start printing from different workstations or even from off-site, which proves beneficial for collaborative designs or batch productions.

Additionally, Formlabs pays attention to feedback from its user community. Updates based on user inputs ensure that the functionality aligns with real-world needs. For instance, the Form 4 includes improved error handling algorithms that provide clearer instructions on mitigating common printing issues, reducing the frustration levels that may arise in complex print jobs.

The overall experience of using the Form 4 is characterized by ease of use, flexibility in operation, and a focus on user-centered design, helping both novice and expert users feel equipped to handle their projects effectively.

Design and Usability Enhancements

The design and usability of 3D printers are essential not only for aesthetic appeal but also for functionality and user interaction. The Form 4 has introduced various design enhancements that make it more user-friendly and efficient. Firstly, the printer’s footprint has been optimized to occupy less space while maintaining build volume, making it more suitable for cramped workspaces or labs.

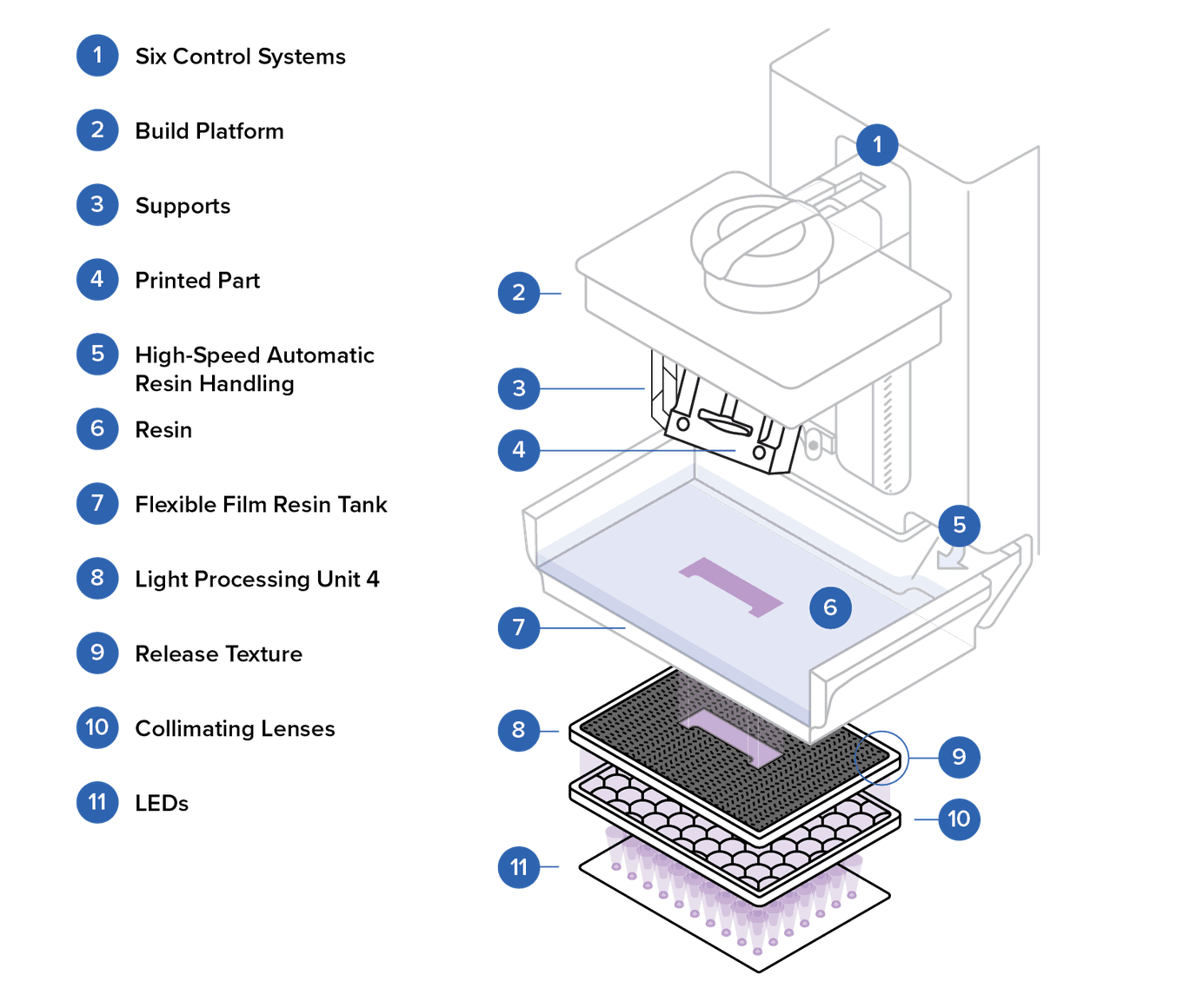

The internal components have undergone improvements: the resin tank is easier to remove and replace, and the entire assembly has been designed to minimize spillage, which is often a concern in resin-based 3D printing. This aspect is particularly advantageous in environments where multi-material printing is common, as frequent tank changes are required.

The build platform on the Form 4 has been redesigned for increased adherence and removal post-printing. For instance, the shape and texture of the platform enhance stability during the printing process while allowing for easier detachment of printed objects post-curing. This addresses a common pain point observed with earlier models, where prints were occasionally damaged during removal due to strong adhesion.

Furthermore, the Form 4 supports multiple polymer materials with varying printing parameters, granting users greater flexibility in their designs. Effective integration of usability features reflects Formlabs’ commitment to providing an accessible and efficient product tailored to the needs of diverse industries.

Software Features and Updates

Software plays an instrumental role in 3D printing workflow management and operational efficiency. The Form 4 benefits from an updated ecosystem that includes the PreForm software, optimized for better slicing capabilities and print preparation. These upgrades result in more reliable and faster slicing, yielding a smoother transition from design to print. The software includes advanced algorithms that ensure better resolution and definition in printed parts, improving complex geometrical accuracy without sacrificing speed.

Moreover, the Form 4 presents enhanced connectivity options through the Formlabs Dashboard, allowing users to manage multiple printers in varied locations from a centralized interface. This feature is advantageous for larger organizations with several printers, as it streamlines the workflow by keeping all jobs organized in one place, reducing the risk of errors and overseeing print statuses effortlessly.

The software also features real-time monitoring and feedback systems. Users receive immediate notifications regarding potential issues, such as material depletion, and can access insights on print performance. This proactive approach to error management dramatically uplifts user experience and minimizes downtime and wasted resources.

Additionally, Formlabs frequently rolls out software updates that enhance functionality based on user feedback, ensuring that customers are equipped with the latest features and tools. This commitment fosters a community around the product and provides users with a sense of support and continuous improvement.

Cost Considerations

When evaluating a 3D printer, cost considerations are paramount for businesses and individuals alike. The upfront price of a printer is often just the beginning; operational costs, maintenance, and the value engendered through its use play key roles in the overall financial assessment.

Pricing of Form 3 and Form 4

When comparing the Form 3 and Form 4, the price point is one of the first aspects customers evaluate. As of late 2023, the entry price for the Form 3 is generally around $3,500, whereas the Form 4 is expected to retail at approximately $4,500. This difference in pricing can be attributed to the innovative features, enhanced speed, and improved user experience the Form 4 provides.

However, potential buyers must consider this initial cost against expected returns. While the upfront investment in the Form 4 is higher, aspects such as increased efficiency and reduced operational time can offset the initial expenditure over time. Businesses that require high product turnover and rapid prototyping will find that the speed and efficiency improvements of the Form 4 yield a quicker ROI compared to the Form 3.

Value for Money Assessment

To assess the value for money that the Form 4 offers compared to the Form 3, it is essential to consider factors beyond mere pricing. For instance, with the Form 4, users can print more complex geometries with fewer supports, leading to material savings. This translates into lower overall production costs in the long run—an important factor for businesses that have tight profit margins.

Furthermore, the advanced software features reduce training time for new users, which is another cost-saving measure that supports a more rapid onboarding process. For example, a design team that can adopt the Form 4 quickly will spend less on training and get products to market faster.

The overall durability and reliability improvements also suggest lower maintenance costs, which enhance the value proposition. Thus, while the Form 4 may carry a higher sticker price, when analyzed through the lens of efficiency gains, material savings, and reduced downtime, it positions itself as a more valuable investment in various manufacturing contexts.

Conclusion

Summary of Key Findings

In comparing the Formlabs Form 4 and Form 3, several key enhancements manifest. The Form 4 offers notable improvements in speed and efficiency, achieving higher build speeds and streamlined workflows that significantly benefit production time. User experience and usability have been enhanced with a more intuitive interface, refined design for easier maintenance, and better post-processing capabilities. Software updates and efficient slicing methods further improve operational reliability, elevating performance standards across diverse applications.

From a cost perspective, while the Form 4 comes with a higher initial investment, its long-term value proposition is compelling when considering its efficiency, material utilization, and improved user productivity.

Recommendations for Potential Buyers

For potential buyers, determining the right fit between the Form 3 and Form 4 hinges on specific needs and applications. If the primary focus is on faster turnaround times and the need for advanced functionalities, the Form 4 is the superior choice, offering greater returns in high-demand environments. Conversely, smaller operations or hobbyists not requiring high production volume may find the Form 3 adequate for their needs while benefiting from a lower initial investment.

Ultimately, investing in the Form 4 is highly recommended for organizations looking to scale their operations and innovate faster in a competitive landscape. Overall, both models showcase the dedication of Formlabs to quality and user satisfaction, making them strong contenders in the 3D printing market.